The difference between oxidation firing and reduction firing of gosu

Oxidation firing and reduction firing

Both oxidation firing and reduction firing are methods of firing bisque pottery at around 1200-1300℃ after coloring, also known as final firing.Depending on the method of firing, this is divided into oxidation firing and reduction firing.

Oxidation firing is a common firing method in which heat is added to pottery.

In reduction firing, a large amount of gas is let into the kiln when the temperature reaches about 945-950℃ during the final firing of pottery. This lowers the oxygen concentration inside the kiln.

The oxygen concentration varies depending on the potter, but it is often set to 10% or less. In this case, the gas removes the oxygen contained in the pottery, so it is called reduction firing.

Reduction firing is often done in a gas kiln, while oxidation firing is often done in an electric kiln.

This time, we tested the following eight types of gosu.

・China Cobalt Blue No. 1

・Tang Gosu No. 2

・Blue and cobalt blue

・Ancient No.3

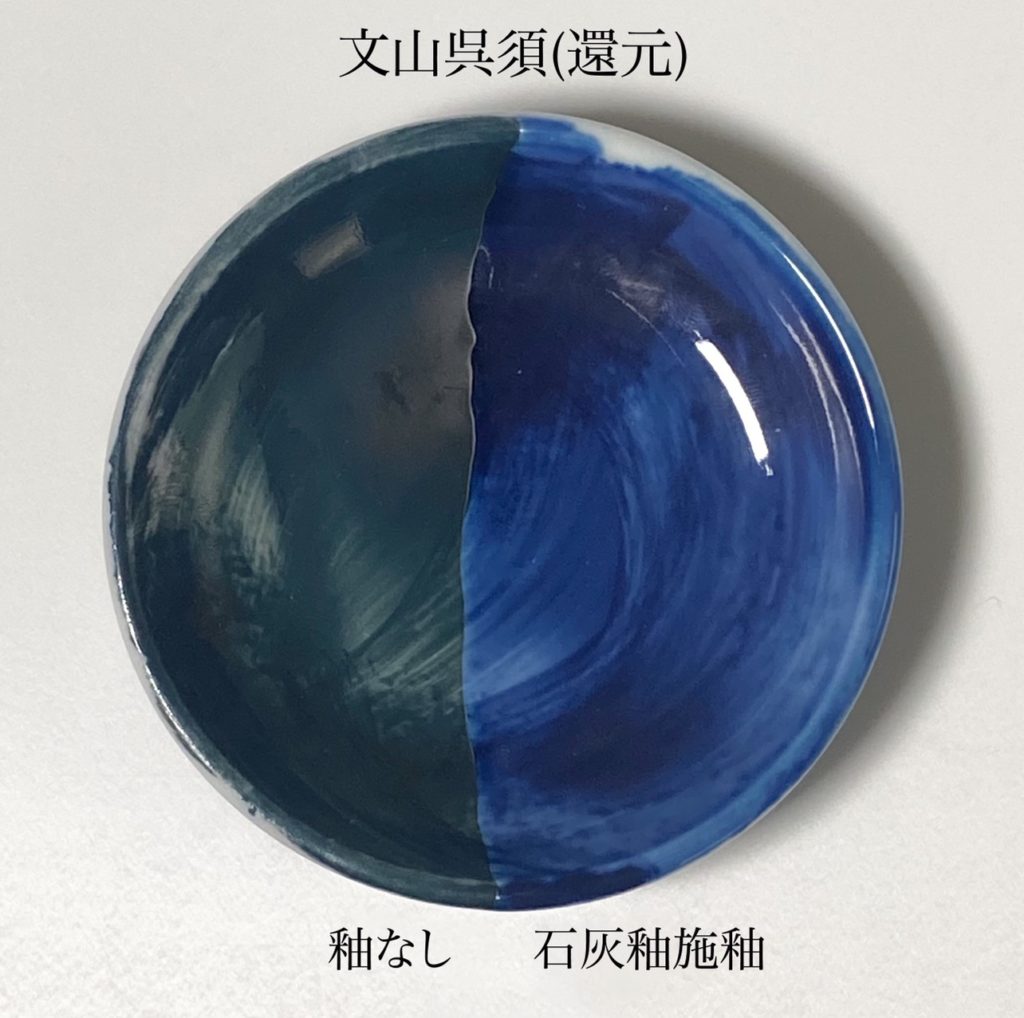

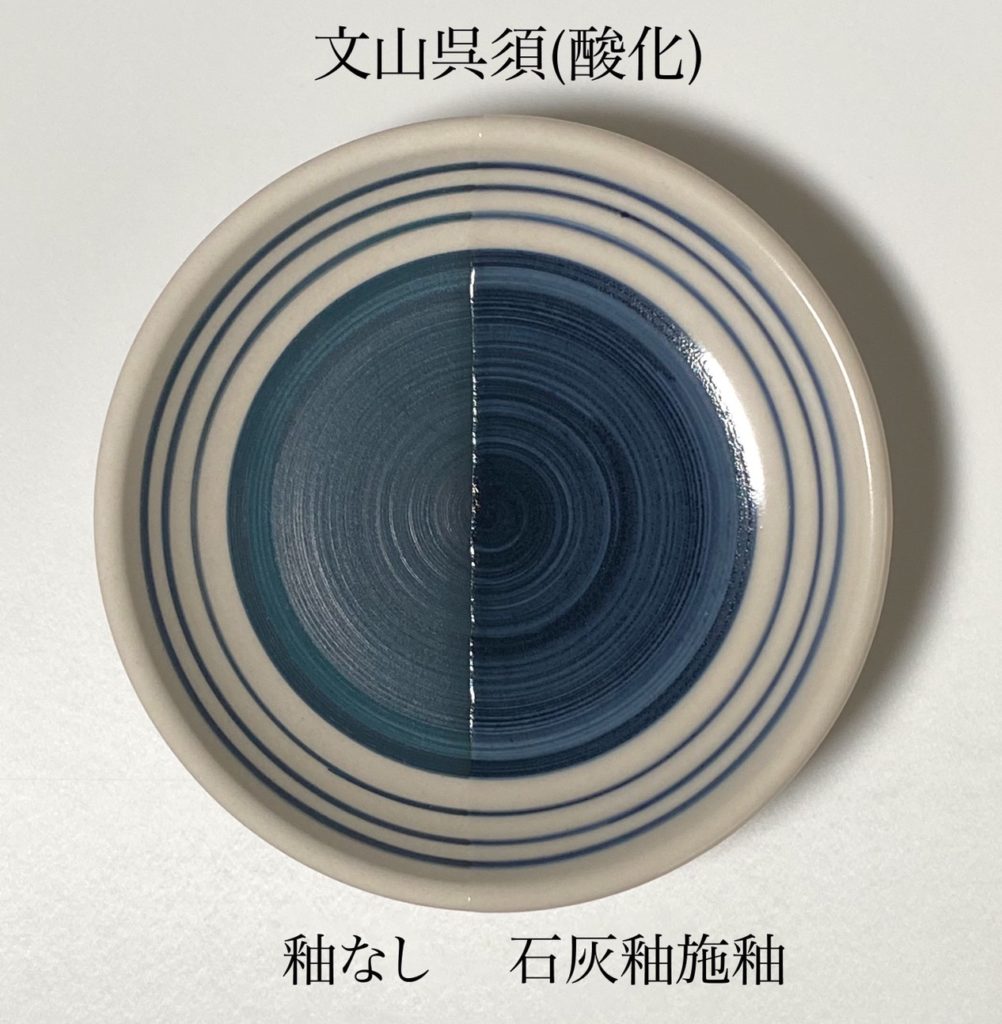

・Bunzan cobalt blue

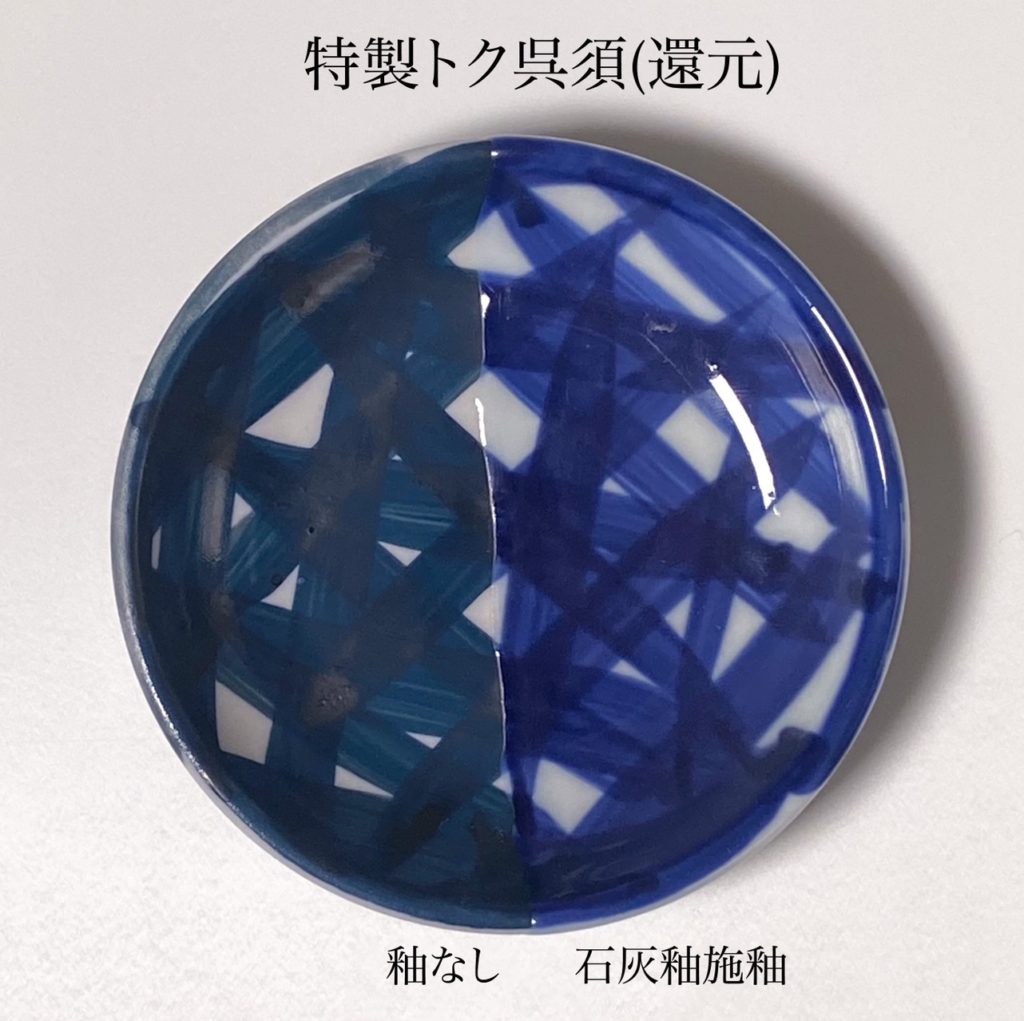

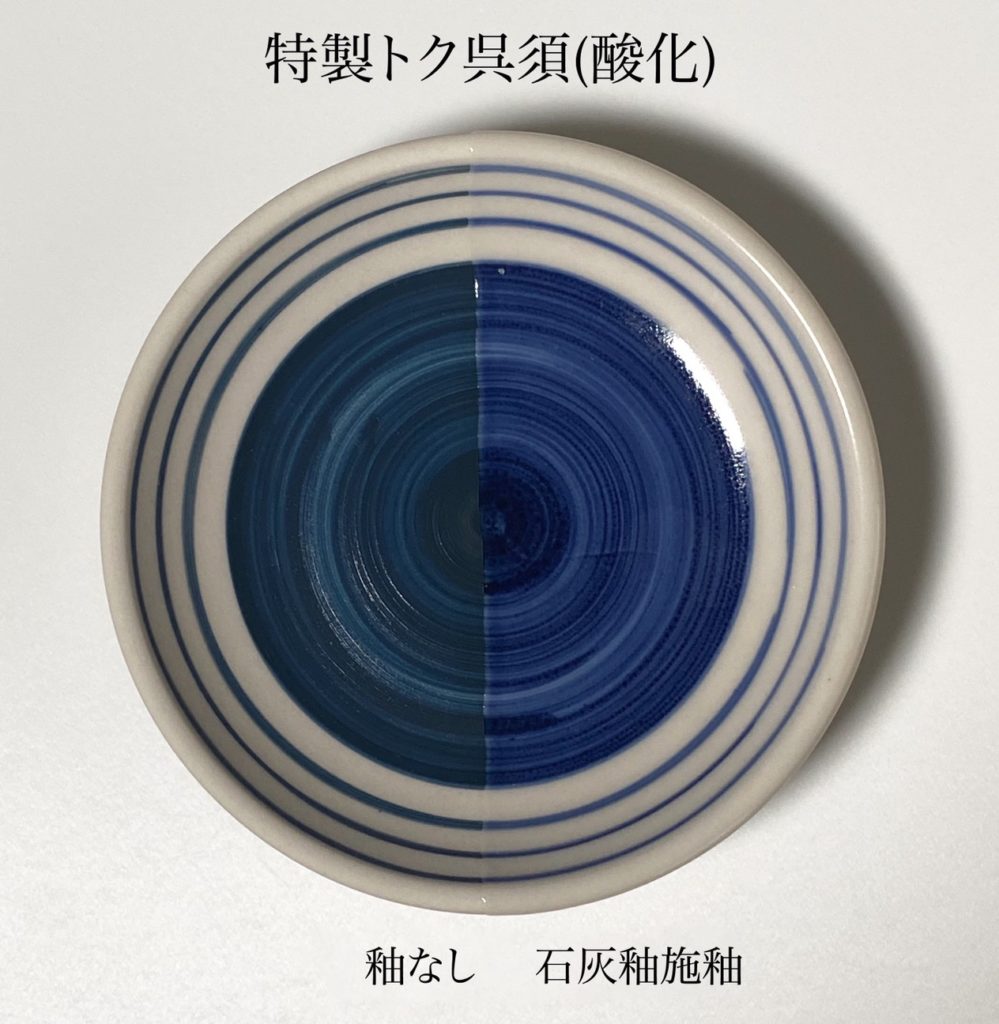

・Special gosu

・Ink and cobalt blue

・Kaihei

Conditions for reduction firing of gosu

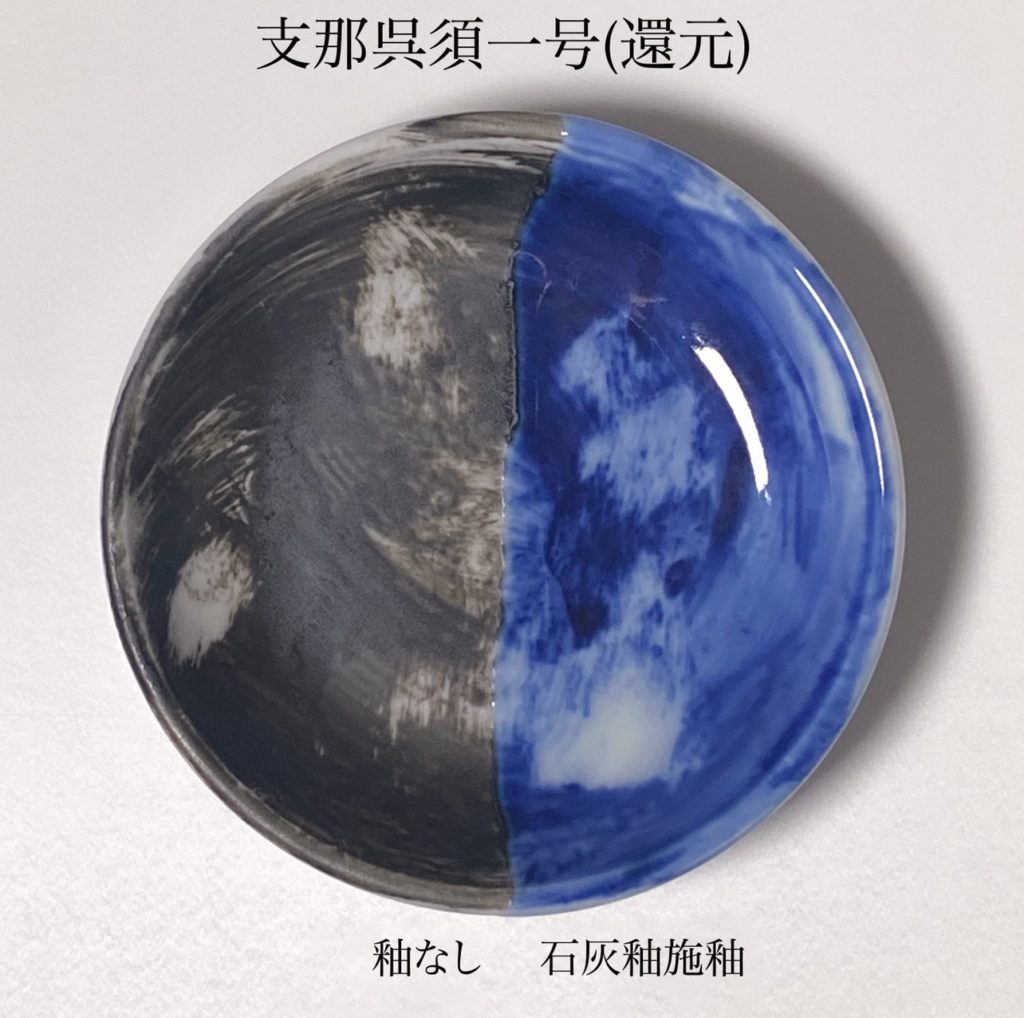

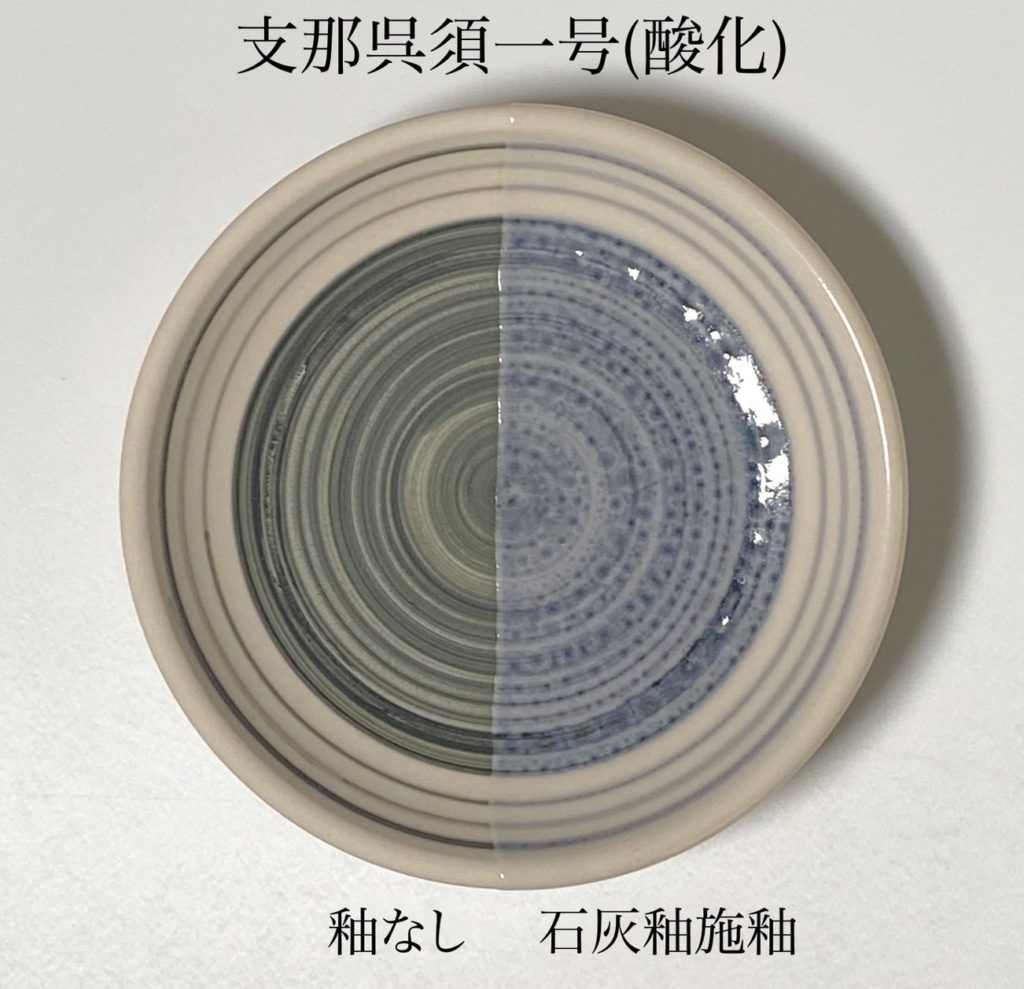

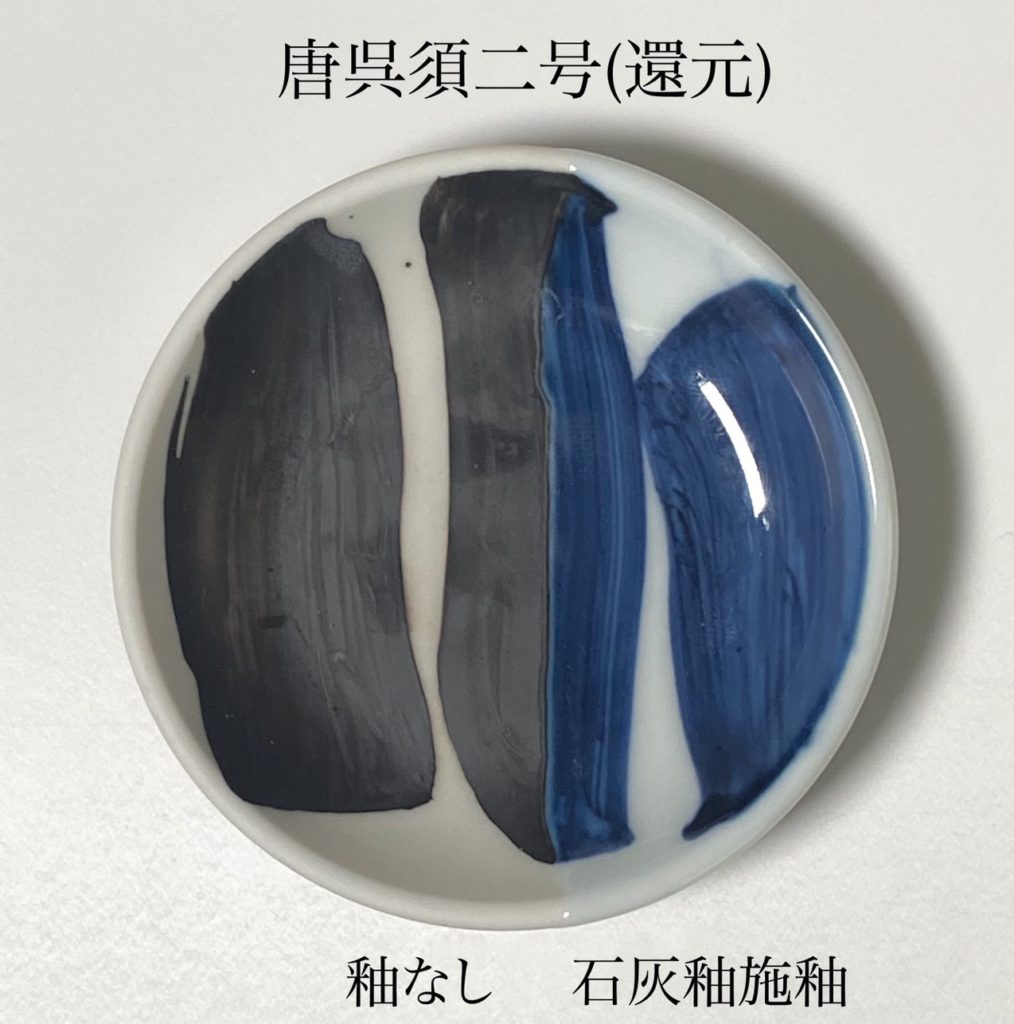

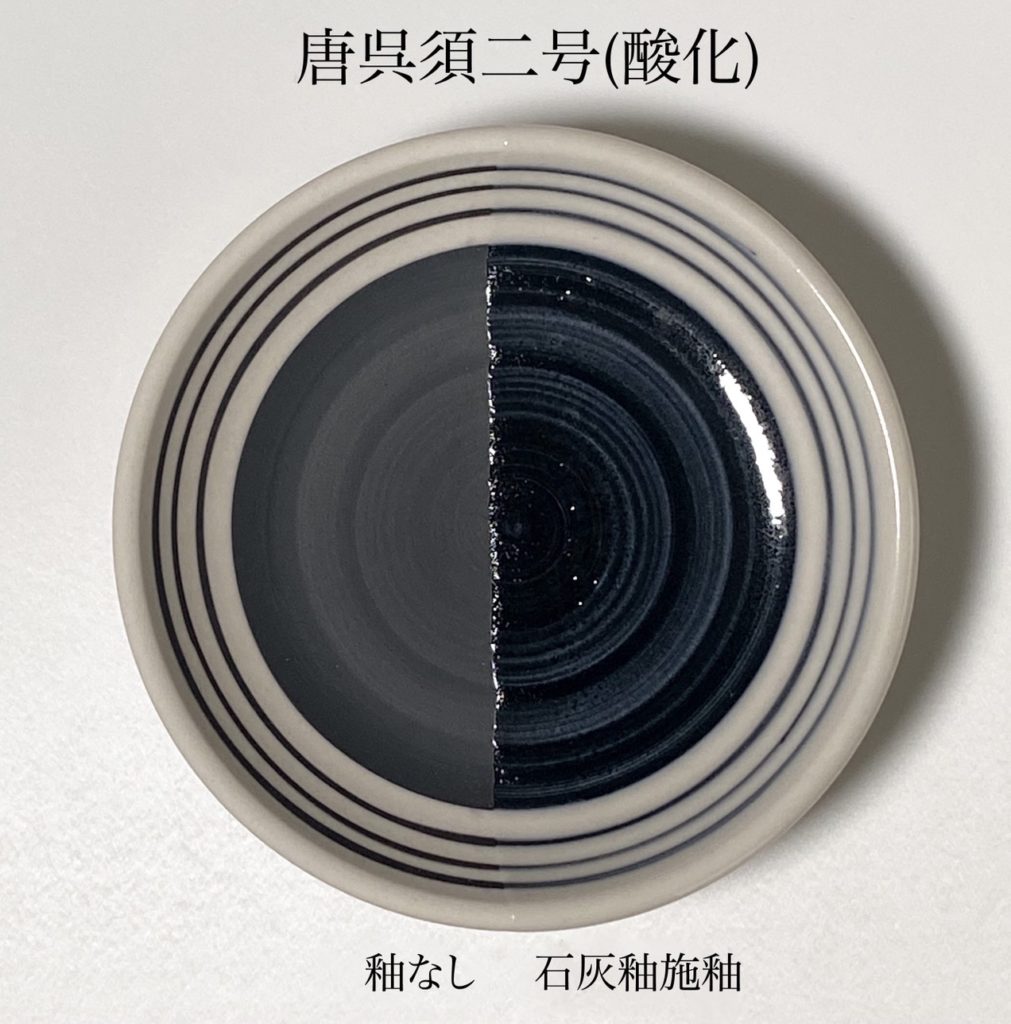

Gosu is generally fired by reduction firing. You can see the actual products that have been fired by our company. The clay used for the porcelain is Amakusa Eri Naka. The firing conditions are 1250℃.

Conditions for oxidizing and firing gosu

Next, we will show the case of oxidation firing of gosu. The clay used for the porcelain is Amakusa Eri Naka, the same as for reduction firing. The firing conditions are 1230℃.

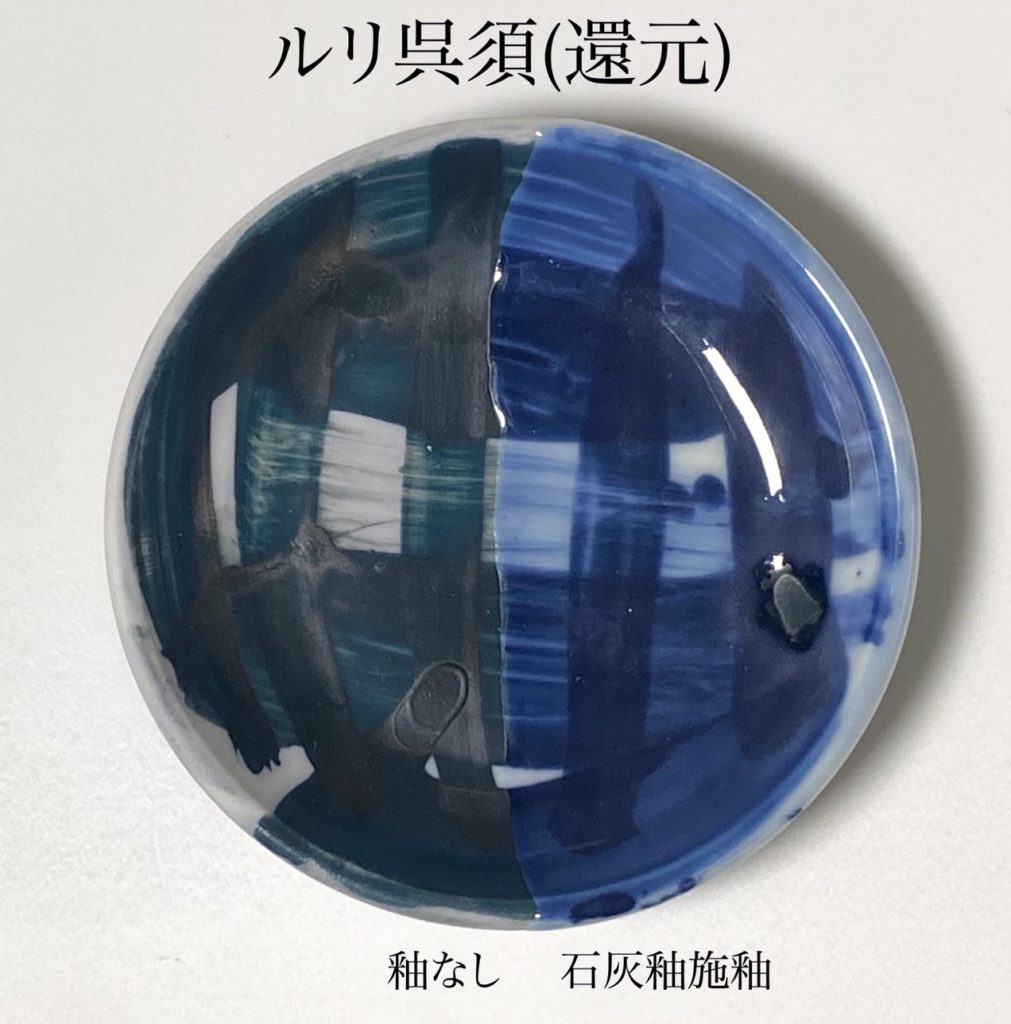

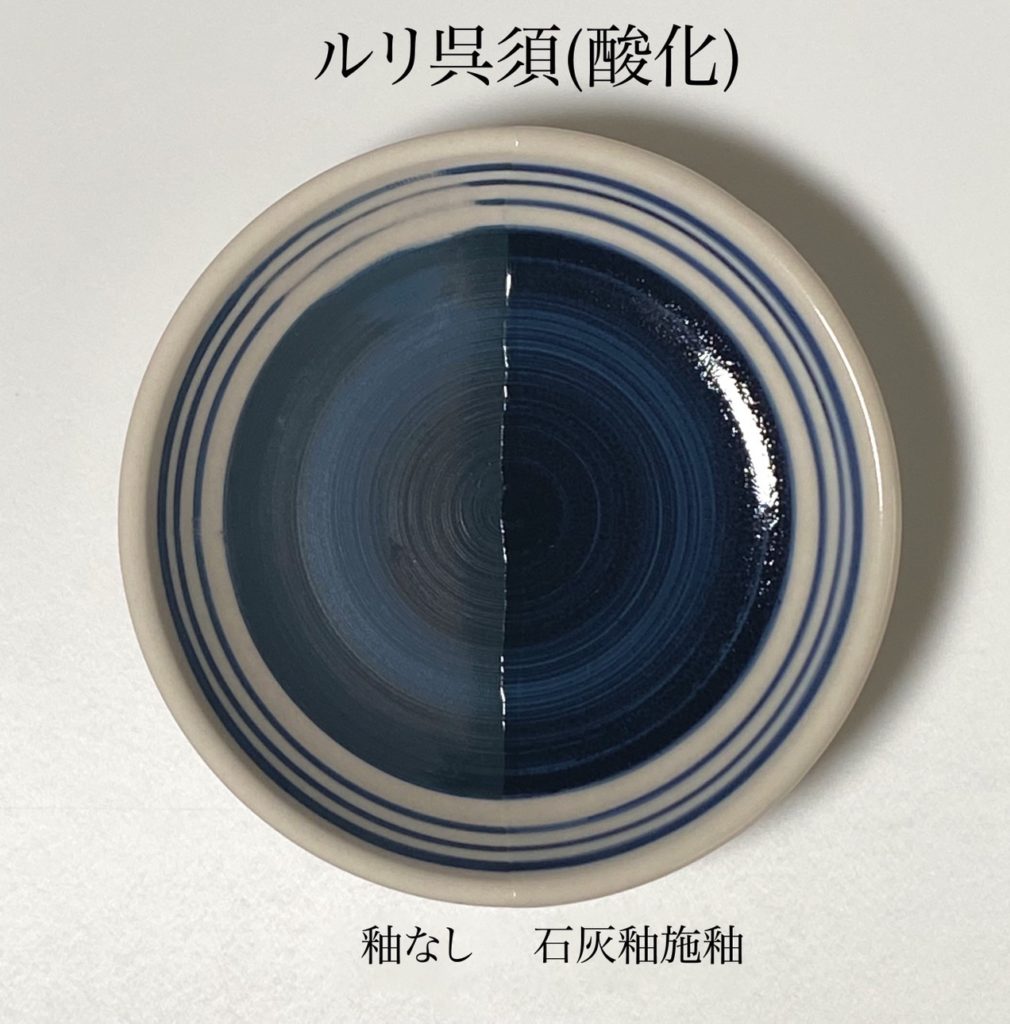

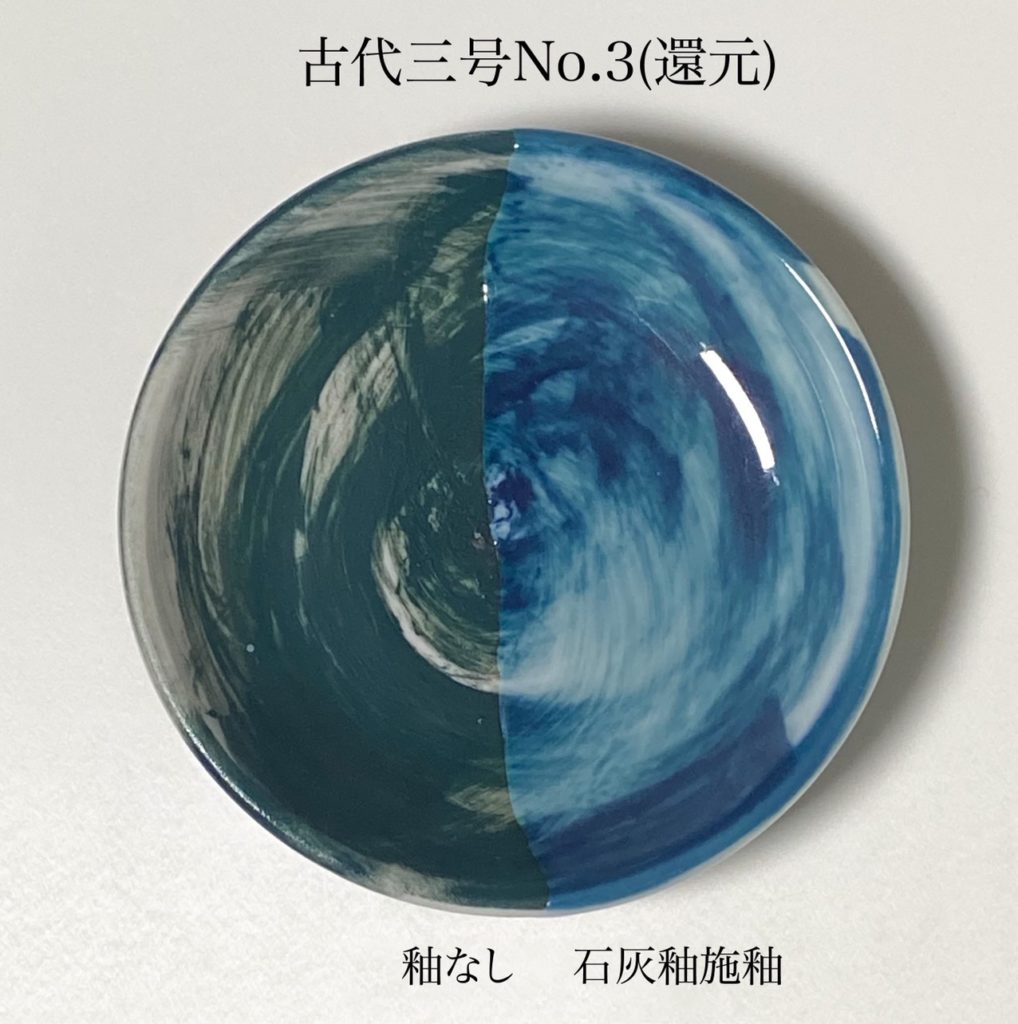

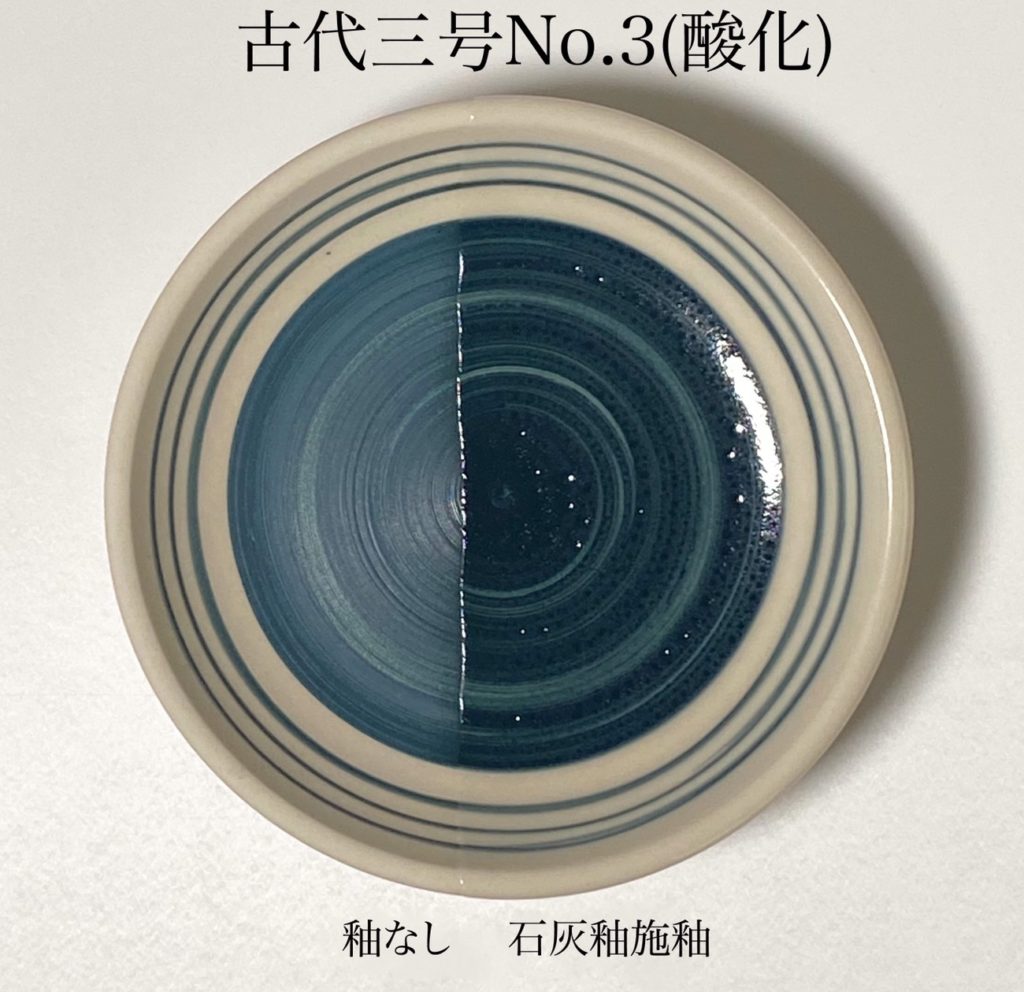

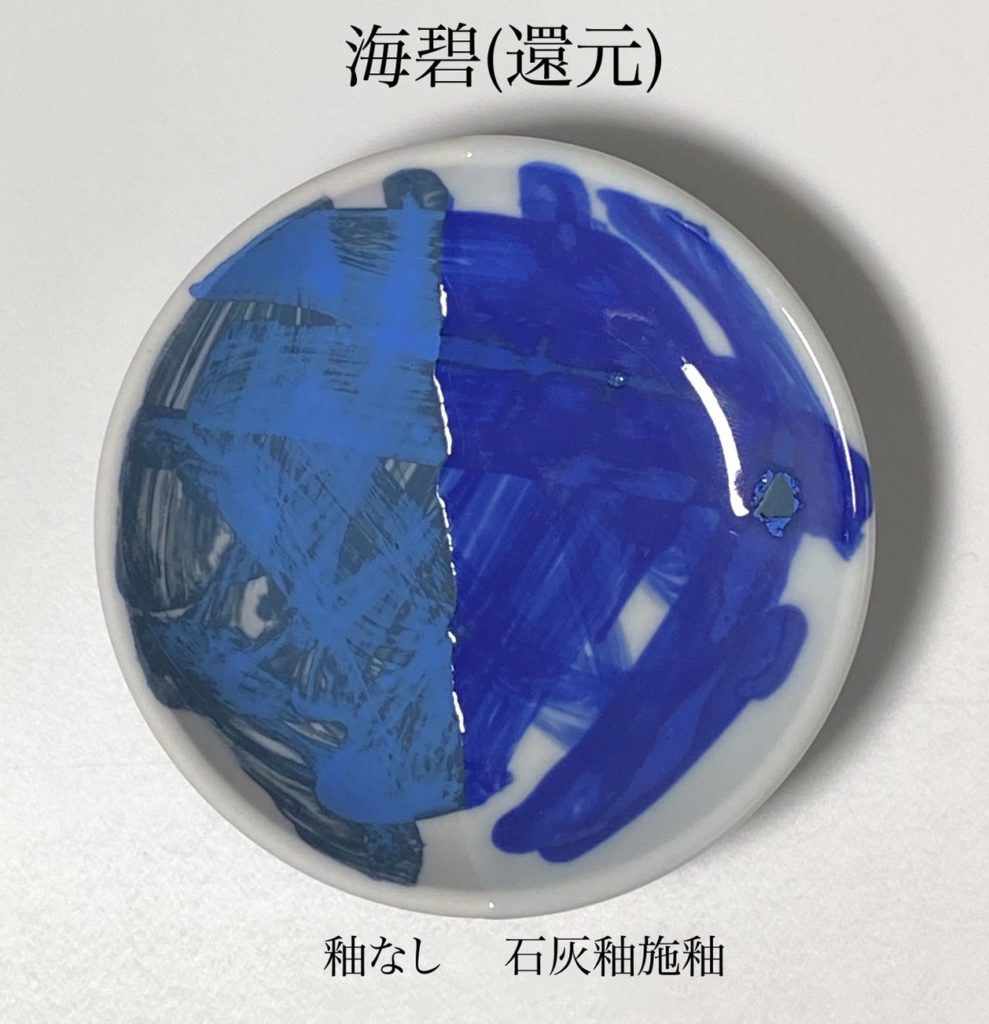

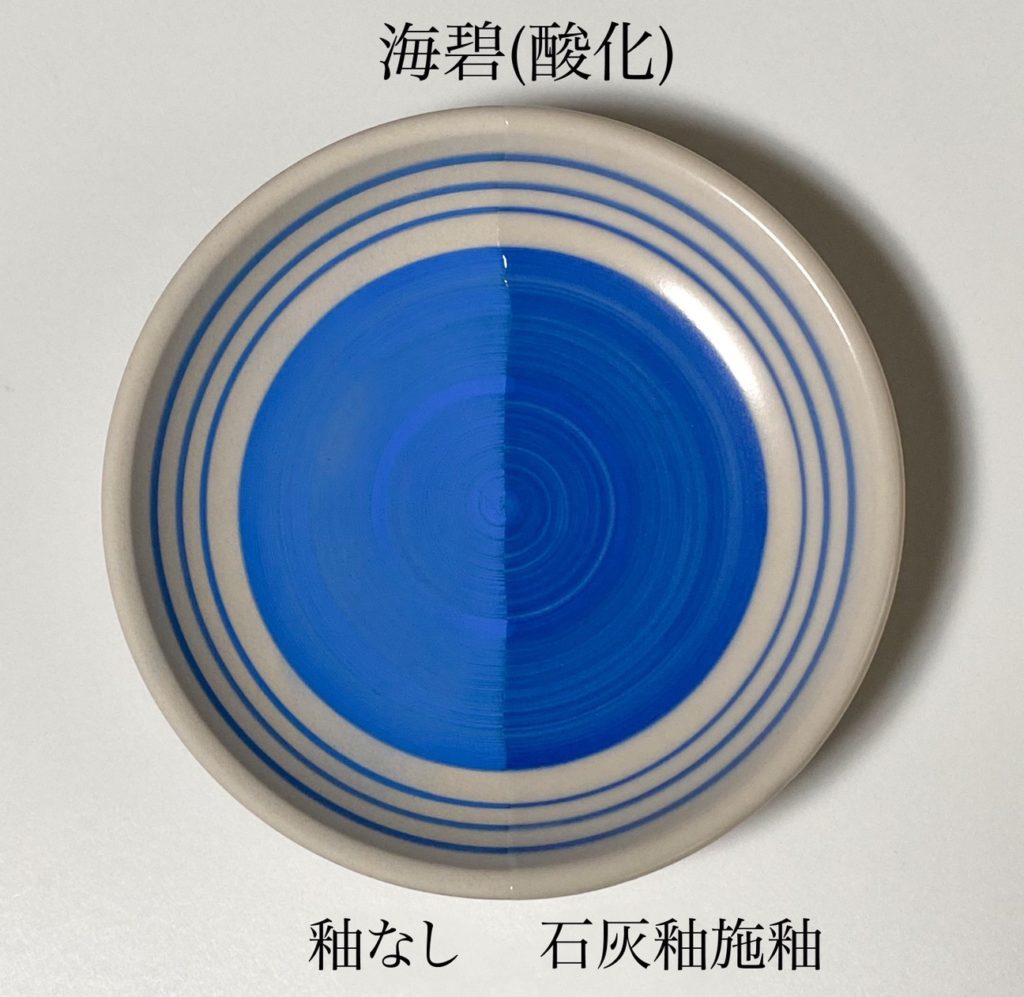

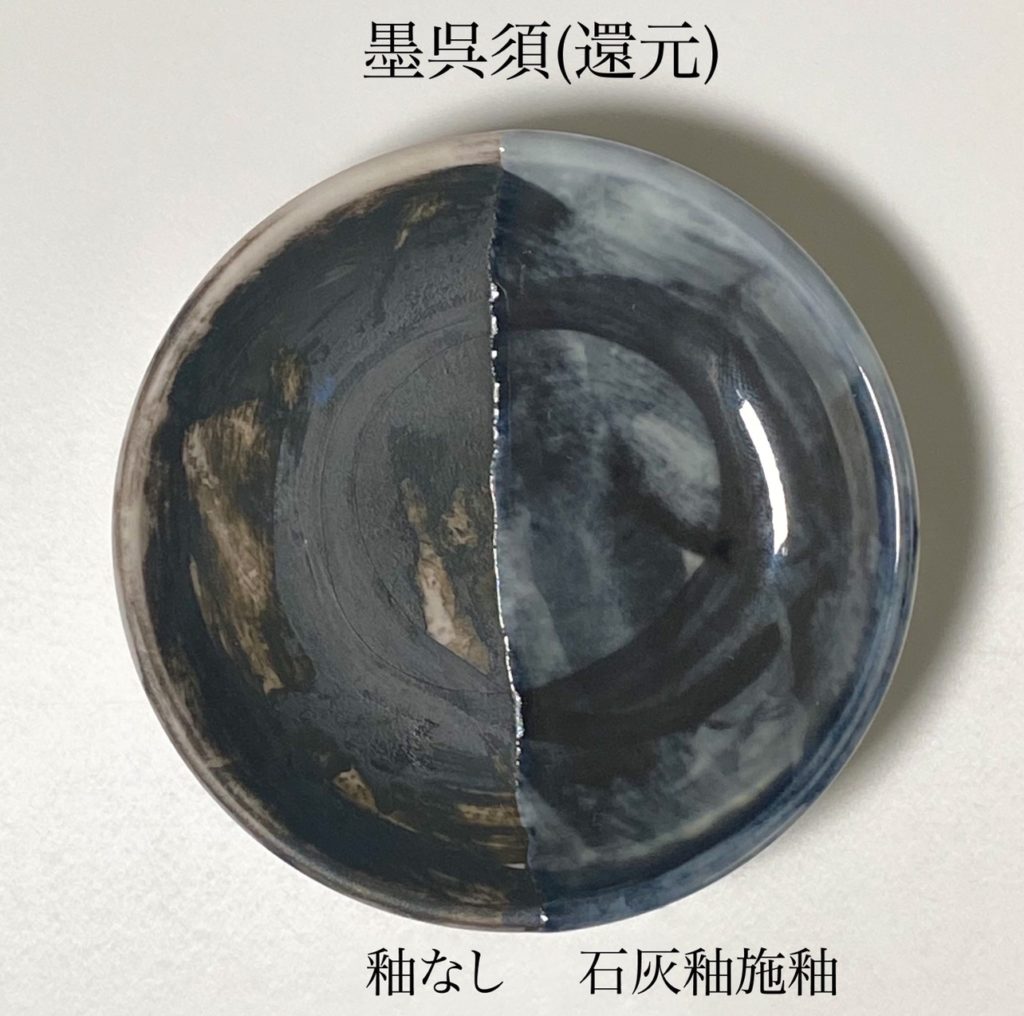

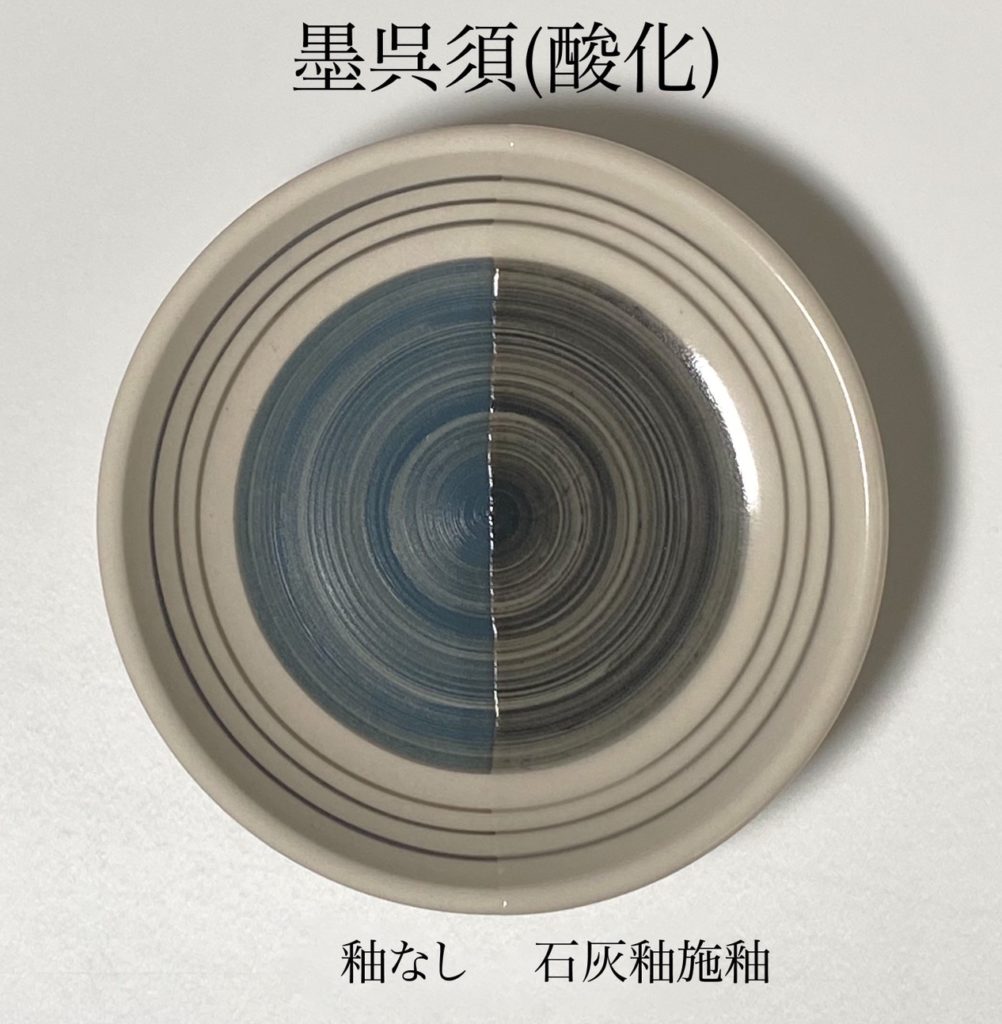

Comparison of oxidation and reduction of each gosu

The left column shows reduction firing of gosu, and the right column shows oxidation firing of gosu. The same sample plate on the left was fired without any glaze applied, just with gosu applied. The same sample plate on the right was fired with a lime glaze (white glaze) that is generally used for blue and white porcelain after applying gosu. They are arranged from top to bottom in order of the greatest change in color with and without glaze.

| Reduction firing | Gosu Oxidation firing |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

We found that the difference between having or not having glaze applied and the difference between oxidation-reduction firing varies depending on the type of gosu.

Furthermore, with regard to the unglazed Kaiheki ware, the gosu tends to adhere easily when the surface is rubbed.

This time we introduced the difference between oxidation firing and reduction firing of gosu.

Over the years, we have been adjusting the balance of our gosu to harmonize the atmosphere of the pattern and the gosu color.

If you would like to purchase our synthetic gosu, you can do so from this link.